In the summer of 2023, Vasileios Tsianos, the vice president of corporate development at Neo Performance Materials, started getting calls from government officials on both sides of the Atlantic. Within the world of industrial material manufacturing, Neo is best known for making rare earth magnets, used in everything from home appliances to electric vehicles. But these calls weren’t about rare earths. They were about something considerably rarer: the metal gallium.

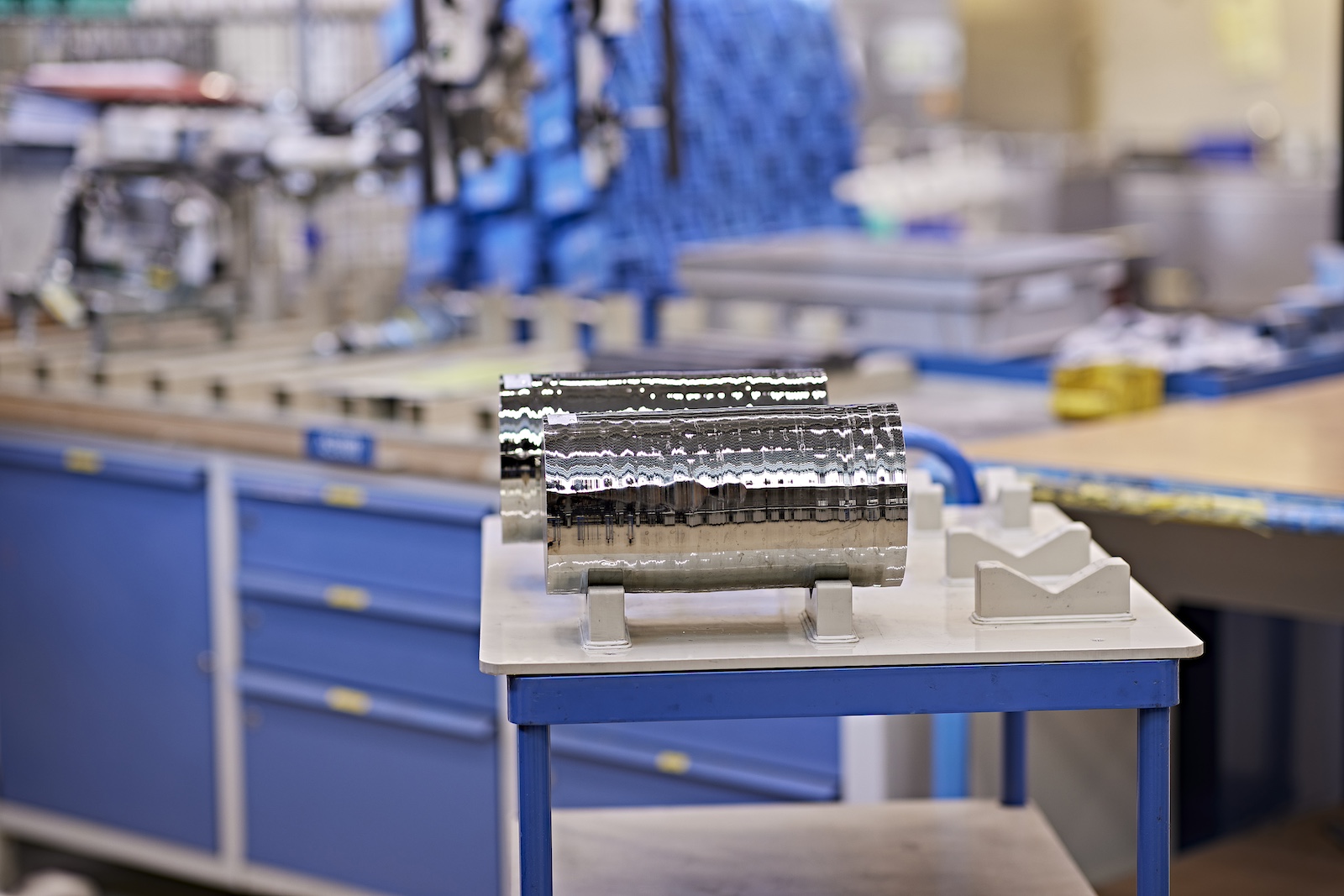

Neo recycles a few dozen tons of high-purity gallium a year, mostly from semiconductor chip manufacturing scrap, at a factory in Ontario, Canada. In North America, it’s the only industrial-scale producer of the metal, which is used in not only chips, but also clean energy technologies and military equipment.

China, the world’s leading producer by far, had just announced new export controls on gallium, apparently in response to reports that the United States government was considering restrictions on the sale of advanced semiconductor chips to China.

All of a sudden, people wanted to talk to Neo. “We’ve spoken to almost everyone” interested in producing gallium outside of China, Tsianos told Grist.

Since Tsianos started receiving those calls, tensions over the 31st element on the periodic table — as well as the 32nd, germanium, also used in a bevy of advanced technologies — have escalated. In December, China outright banned exports of both metals to the United States following the Biden administration’s decision to further restrict U.S. chip exports.

Now, several companies operating in the U.S. and Canada are considering expanding production of the rare metals to help meet U.S. demand. While Canadian critical minerals producers may get swept up in a new geopolitical tit-for-tat should Trump go through with his threat to impose tariffs, U.S. metal producers could see support from the new administration, which called for prioritizing federal funding for critical minerals projects in a Day 1 executive order. Beyond the U.S. and Canada, industry observers say China’s export ban is fueling global interest in making critical mineral supply chains more diverse so that no single country has a chokehold over materials vital for a high-tech, clean energy future.

“This latest round of export bans are putting a lot of wind in the sails of critical minerals supply chain efforts, not just in the U.S. but globally,” Seaver Wang of the Breakthrough Institute, a research center focused on technological solutions to environmental problems, told Grist.

Gallium and germanium aren’t exactly household names. But they are found in products that are indispensable to modern life — and a fossil fuel-free society. With its impressive electrical properties, gallium is used in semiconductor chips that make their way into everything from cell phones to power converters in electric vehicles to LED lighting displays. The metal is also used in the manufacturing of rare earth magnets for electric vehicles and wind turbines, in thin film solar cells, and sometimes, in commercially popular silicon solar photovoltaic cells, where it can help increase performance and extend lifespan.

Baris Seckin / Anadolu via Getty Images

Germanium, meanwhile, is used to refract light inside fiber optic cables. In addition to helping form the backbone of the internet, the metal’s exceptional light-scattering properties make it useful for infrared lenses, semiconductor chips, and high-efficiency solar cells used by satellites.

There aren’t many substitutes for these two elements. Some silicon-based semiconductors lack gallium, and specialized glasses can be substituted for germanium in certain infrared technologies. Solar cells are often doped with boron instead of gallium. But these two metals have specific properties that often make them the ideal material. When it comes to clean energy, Tsianos told Grist, there are no substitutes “within the material performance and cost trade-off spectrum” offered by gallium.

Because a little bit goes a long way, the market for both metals is small — and it’s dominated by China. In 2022, the world produced about 640 tons of low-purity gallium and a little over 200 tons of germanium, according to the U.S. Geological Survey. In recent years, China has accounted for virtually all of the world’s low-purity gallium output and more than half of refined germanium.

That’s partly due to the fact that both metals are byproducts of other industries. Gallium is typically extracted from bauxite ores as they are being processed to make aluminum oxide, while zinc miners sometimes squeeze germanium out of waste produced during refining. China is a leading producer of these common metals, too — and its government has made co-extracting gallium and germanium a priority, according to Wang. “It is very strategic,” he said.

China’s dominance of the two metals’ supply chains gives it a considerable cudgel in its ongoing trade war with the U.S. America produces no virgin gallium and only a small amount of germanium, while consuming approximately fifty tons a year of the two metals combined. A U.S. Geological Survey study published in November found that if China implemented a total moratorium on exports of both metals, it could cost the U.S. economy billions. Weeks after that study was published, China announced its ban.

The ban is so new that it’s not yet clear how U.S. companies, or the federal government, are responding. But America’s high-tech manufacturing sector isn’t without fallback options. North of the border, Neo’s facility in Ontario stands ready to double its production of gallium, according to Tsianos. “We have the capacity,” he told Grist. “We’re waiting for more feedstock.”

Currently, Neo’s only source of gallium is the semiconductor industry. Chip makers in Europe, North America, and Asia send the company their scrap, which it processes to recover high-purity gallium that feeds back into semiconductor manufacturing. But Tsianos says Neo is piloting its technology with bauxite miners around the world to create new sources of virgin gallium. The idea, he says, is that bauxite miners would do some initial processing on-site, then send low-purity gallium to Neo for further refining in Canada. Tsianos declined to name specific bauxite firms Neo is partnering with, but said the company is “making progress” toward making new resources available.

Meanwhile, in British Columbia, mining giant Teck Resources is already a leading producer of germanium outside of China. The firm’s Trail Operations refinery complex receives zinc ore from the Red Dog mine in northwest Alaska and turns it into various products, including around 20 tons of refined germanium a year, according to a U.S. Geological Survey estimate. (Teck doesn’t disclose production volumes.)

That germanium is sold primarily to customers in the U.S., Teck spokesperson Dale Steeves told Grist. In wake of the export ban, Steeves said that the firm is now “examining options and market support for increasing production capacity of germanium.”

Umicore

Kwasi Ampofo, the head of metals and mining at the clean energy research firm BloombergNEF, told Grist that in the near term, he would expect the U.S. to “try to establish new supply chain relationships” with countries that already have significant production, like Canada, to secure the gallium and germanium it needs. That may be true whether or not Trump’s proposed tariffs on Canadian imports become reality. Tsianos was bullish in spite of the tariff threat, noting in an email that Neo “remains the only industrial-scale and commercially-operating Gallium facility in North America.”

“[W]e are committed to continue serving our European, American, and Japanese customers in the semiconductor and renewable energy industries,’ Tsianos added.

Steeves told Grist that a trade war between the U.S. and Canada would be “a negative for the economy of both nations, disrupting the flow of essential critical minerals and increasing costs and inefficiencies on both sides of the border.” Teck, he said, “will continue to actively manage our sales arrangements to minimize the impact to Trail Operations.”

While Canada may be the U.S.’s best short-term option for these rare metals, farther down the line Ampofo expects to see the U.S. take a “renewed interest” in recycling — particularly of military equipment. In 2022, the Department of Defense announced it had initiated a program for recovering “optical-grade germanium” from old military equipment. At the time, the initiative was expected to recycle up to 3 tons of the metal each year, or roughly 10 percent of the nation’s annual demand. The Defense sub-agency responsible for the program didn’t respond to Grist’s request for comment on the program’s status.

There’s another small source of production capacity in the U.S. The global metals company Umicore recycles germanium from manufacturing scrap, fiber optic cables, solar cells, and infrared optical devices at an optical materials facility in Quapaw, Oklahoma, as well as in Belgium. The company has been recycling germanium since the 1950s, a spokesperson told Grist, calling it a “core and historical activity at Umicore.” Umicore declined to disclose how much of the metal it recycles and wouldn’t say whether China’s export ban will impact this part of its business.

While recycling is able to fill some of the nation’s gallium and germanium needs, there may be a larger source of both metals lurking in sludge ponds in central Tennessee.

There, in the city of Clarksville, the Netherlands-headquartered Nyrstar operates a zinc processing facility that produces wastes containing gallium and germanium. A U.S. Department of Energy spokesperson told Grist that the company has previously partnered with Ames National Laboratory’s Critical Materials Innovation Hub to develop processes for extracting gallium, which isn’t typically produced from zinc waste.

Nyrstar

In 2023, Nyrstar announced plans to build a new, $150-million facility, co-located with its existing zinc smelter in Clarksville, capable of producing 30 tons of germanium and 40 tons of gallium a year. However, the current status of the project is uncertain, with no timetable to begin construction. A spokesperson for Nyrstar told Grist the company is “continu[ing] to work on and evaluate the business case” for the facility, while declining to offer additional details.

Making a business case to produce gallium or germanium is the central challenge for firms outside of China, experts told Grist. As Tsianos of Neo put it, these metals are a “side hustle” that requires major up-front investment for a relatively small amount of extra revenue. Moreover, a bauxite or zinc miner’s ability to produce gallium or germanium typically hinges on the market conditions for the metal it is primarily focused on. That means “if aluminum prices are low or the zinc prices are low, the mine or the smelter might just not operate, even if the world is sort of screaming out for more gallium or germanium,” Wang said.

Still, there’s more economic incentive to produce these metals now than there was a few years ago. The recent geopolitical drama, Tsianos says, has caused a “bifurcation” in the price of gallium. Outside of China, the price of the metal is now “almost double” what it is within the nation’s borders.

“There’s a structural change in the market that has created a business case for outside of China production,” Tsianos said. “And it started because of the export control.”

This story was originally published by Grist with the headline 2 obscure clean energy metals are caught in the crosshairs of the US-China trade war on Feb 7, 2025.

After a Chinese export ban, can America get gallium and germanium from Canada — or will tariffs get in the way? Economics, Energy, Technology Grist